Secondary Operations

Why you need secondary operations?

One of the main reasons for performing secondary operations is to achieve a specific design or functional requirement that cannot be achieved through the primary manufacturing process alone. For example, a metal sheet may need to be cut into a specific shape or have holes drilled in it for assembly purposes. This secondary operation is necessary to ensure that the final product meets the desired specifications.

Secondary operations also play a crucial role in enhancing the aesthetics of a product. By using techniques such as polishing, painting, or coating, manufacturers can improve the surface finish of a product and make it more visually appealing to consumers. This not only adds value to the product but also helps create a positive brand image.

What are the benefits?

Improved functionality: Secondary operations can be used to add functional features to a product that cannot be achieved through the primary manufacturing process alone. This helps create a more versatile and useful final product.

Enhanced aesthetics: Secondary operations like surface finishing can greatly improve the appearance of a product, making it more visually appealing to consumers. This can also help differentiate a product from its competitors and attract potential customers.

Customization: Secondary operations allow for greater customization of products to meet specific design or functional requirements. This not only adds value to the product but also helps cater to different customer needs and preferences.

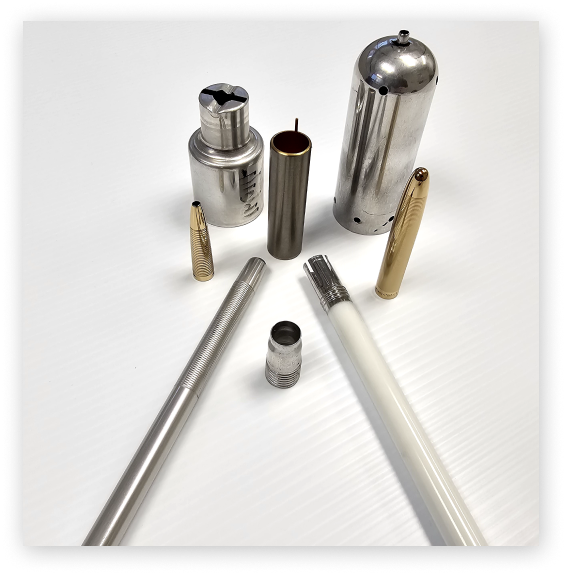

Custom Metal Finishing

Nickel and chrome plating not only enhance the aesthetic appeal of metals but also significantly increase their durability and resistance to corrosion. This makes them popular choices for a wide range of applications, from automotive parts to household appliances.

Powder coating provides a durable and environmentally friendly finish for metals, offering superior resistance against corrosion, scratches, and fading. Its versatility allows for a wide range of color options and finishes, catering to diverse aesthetic preferences and industrial needs.

Electrostatic applied lacquer utilizes an electric charge to adhere the paint to the metal surface efficiently and evenly. This method ensures a smooth, high-quality finish with no drips or runs.

Metal polishing enhances the surface quality of metals, producing a smooth, reflective finish. It removes imperfections and prepares the metal for further finishing or application.

We offer other finishing services including, but not limited to:

- Heat Treating

- Anodizing

- Burnishing

- Four Color Lithography

- Surface Detailing

Built for your Industry

Get a Custom Quote Today!

Looking for precision metalworking services tailored to your specific needs? Let’s bring your vision to life! Contact us to receive a personalized quote. Our team is ready to provide you with expert advice and a detailed estimate for your project. Simply fill out our quick form, and we’ll get back to you with a competitive quote that matches your requirements.