Guide

An Introduction to the Deep Drawn Metal Stamping Process

An Introduction to the Deep Drawn Metal Stamping Process

An Introduction to the Deep Drawn Metal Stamping Process

November 26, 2014

Metal stamping processes are one of the most common methods used to shape sheet metal of many different materials into desired shapes. When the depth of the stamped part is equal to or greater than the maximum diameter of the part, it is considered deep drawn.

The deep draw process begins by feeding the desired metal or alloy into the machine either in a continuous strip or by individual sheet. The initial stage cuts out a circular blank to be used in the stamping process.

10 Quick Tips for Choosing a Deep Drawn Metal Stamping Supplier

10 Quick Tips for Choosing a Deep Drawn Metal Stamping Supplier

10 Quick Tips for Choosing a Deep Drawn Metal Stamping Supplier

November 25, 2014

Choosing the right supplier for Deep Drawn Metal Stamping is very important when you want the best results. Listed here are the top ten things to look for to make sure you get the best quality parts, at the best price.

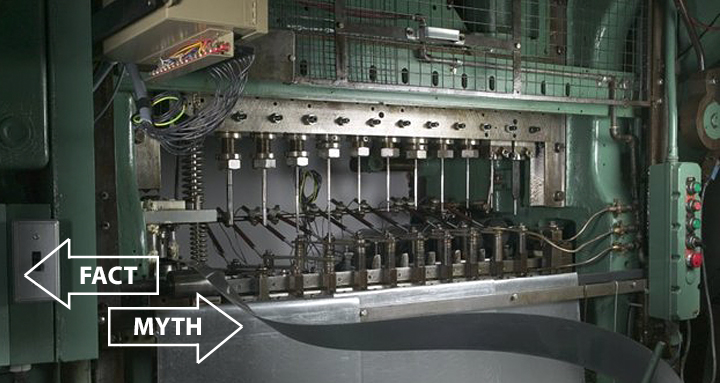

4 Deep Drawn Myths Busted

4 Deep Drawn Myths Busted

4 Deep Drawn Myths Busted

November 12, 2014

Four Signs You Should Invest in Deep Drawn Metal Stamping

Four Signs You Should Invest in Deep Drawn Metal Stamping

Four Signs You Should Invest in Deep Drawn Metal Stamping

November 5, 2014

—- Why Choose Accurate Forming?

—- Why Choose Accurate Forming?

—- Why Choose Accurate Forming?

July 15, 2014

Why Choose Accurate forming LLC

—- Accurate Forming LLC Deep Draw Manufacturing Overview

—- Accurate Forming LLC Deep Draw Manufacturing Overview

—- Accurate Forming LLC Deep Draw Manufacturing Overview

March 25, 2014

Accurate Forming was established in 1955 and is recognized as a leader in the art and science of Deep-Draw Metal Forming.

—- Deep Draw Metal Stamping: What We Do

—- Deep Draw Metal Stamping: What We Do

—- Deep Draw Metal Stamping: What We Do

March 14, 2014

Accurate Forming is a Deep Draw Metal Stamper who was established in 1955. All of Accurate Forming’s operations take place in our 70,000 square foot facility located in Hamburg, NJ. Accurate Forming manufactures cylindrical shaped parts using transfer press technology. The size range for these parts ranges from .700” in length with a diameter of 1.562” all the way to 5.44” in length with a .400” diameter. Material thicknesses range from .007” thick up to .062” thick. Materials that are used in the deep draw manufacturing process are aluminum, cold rolled steel, pre-plated crs, stainless steel, copper, brass and other precious metal alloys.

What makes Accurate Forming unique is our ability to produce extremely high quality parts with long lengths, small diameters and very tight tolerances. Let Accurate Forming’s engineering expertise help you design, produce and receive the highest quality part you can get.

—- Deep Draw Metal Stamping Parts Types and Characteristics

—- Deep Draw Metal Stamping Parts Types and Characteristics

—- Deep Draw Metal Stamping Parts Types and Characteristics

February 27, 2014

Deep drawn metal stampings can be classified into 3 categories, simple, average & difficult. Simple drawn parts usually have the following characteristics; Straight one diameter shell, no critical visual requirements, corner radius equal to 3 times material thickness or greater, an overall length of 1 ½ to 2 ½ times the diameter of the part, an overall length tolerance of plus or minus .005, a wall thickness of .010 – .020 and a tolerance for the outside or inside diameter of the part of plus or minus .002.

—- Deep Draw Metal Stamping Fundamentals

—- Deep Draw Metal Stamping Fundamentals

—- Deep Draw Metal Stamping Fundamentals

February 17, 2014

Let’s look at the different stations that we can have in the press and their functions. As mentioned previously, the first station is the blanking station. The blank is pierced out of the metal strip and then forced down to the transfer slide which moves the blank to the next station. The second station is called the cupping station. This is where the blank is first reduced. The reduction of the blank should not be any more than 45% of the blanks diameter which will avoid any tearing of the material. Following the second station or cupping station are a series of deep drawing stations. Depending on the press it is common to have up to 12 to 15 stations to form a finished part.

—- Accurate Forming: Deep Draw Metal Stamping Fundamentals, Part 2

—- Accurate Forming: Deep Draw Metal Stamping Fundamentals, Part 2

—- Accurate Forming: Deep Draw Metal Stamping Fundamentals, Part 2

January 28, 2014

The blank for the part to be drawn is removed from the strip and moved into the transfer slide. The transfer slide carries the blank to the first draw operation or station. At this station the blank is drawn to its first shape. The transfer slide then returns to its original position and is now ready to accept the next blank.