Blog

Deep Drawn Metal Stamping: Tolerances, Cost Drivers & Best Practices

Deep Drawn Metal Stamping: Tolerances, Cost Drivers & Best Practices

Deep Drawn Metal Stamping: Tolerances, Cost Drivers, and Design Rules

Deep drawn metal stamping is a forming process used to produce seamless, hollow metal parts at production scale. Engineers typically evaluate deep drawn stampings when part depth, structural integrity, or repeatability make machining or shallow stamping inefficient.

This article walks through the process first, then explains when deep drawing makes sense, how tolerances behave, what drives cost, and how to design parts that scale into high-volume production.

How Deep Drawn Metal Stamping Works

Deep drawing forms a flat metal blank into a hollow shape by pulling material into a die cavity using a punch. The material flows plastically rather than being cut, which creates a seamless part with work-hardened strength.

Depending on depth and geometry, parts may require multiple draw stages, trimming, or secondary forming. Each added step improves control but increases cost and tooling complexity.

Understanding this sequence is critical because tolerances, cost, and quality are all tied to how many operations are required.

When Deep Drawn Stampings Are the Best Choice

Deep drawn metal stamping is typically the right solution when:

- The part must be seamless and weld-free

- Depth exceeds what shallow stamping can form

- Consistent wall structure is required

- Production volumes justify dedicated tooling

- Secondary operations can be minimized or integrated

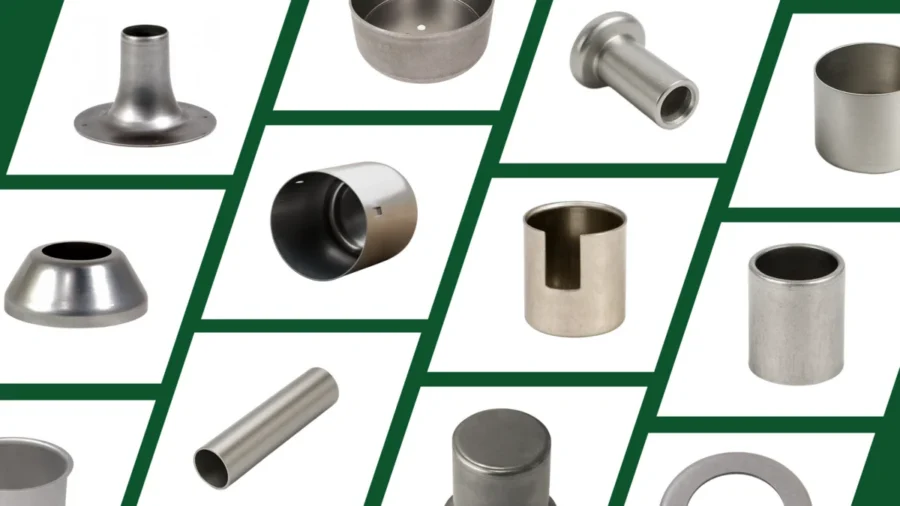

Common examples include metal cups, housings, shells, covers, and enclosures.

How Tolerances Behave in Deep Drawing

Deep drawing is a forming process, not a precision machining operation. Tolerances vary by feature and are influenced by material flow and springback.

Outside diameters are often controlled after drawing through trimming or sizing. Wall thickness varies naturally through the part, with thinning along the walls and thicker material at the base. Overall height is affected by draw depth, springback, and trim strategy. Roundness depends on material properties, draw balance, and tooling condition.

Tighter tolerances generally require secondary operations. Engineers should identify which dimensions are functionally critical and allow other features to remain form-controlled.

What Has the Biggest Impact on Tolerance

Several factors directly affect dimensional consistency:

- Material thickness and alloy behavior

- Part depth and draw ratio

- Tooling condition and wear

- Springback after forming

- Trim operations and secondary forming

Designs that demand tight tolerances early in the draw sequence increase risk and cost.

Tooling Cost and What Drives It

Tooling is the primary upfront investment in deep drawn metal stamping. Tooling cost increases with:

- High draw ratios requiring multiple redraws

- Complex geometry or non-uniform profiles

- Tight tolerance requirements

- Integrated secondary features

- Less forgiving materials

Costs can often be reduced by simplifying geometry, using larger radii, avoiding unnecessary depth, and locating critical features after the draw. Tooling investment is best suited for repeat, high-volume production where cost can be amortized over many parts.

Deep Drawn Part Design Best Practices

Good design improves both cost and manufacturability:

- Use generous corner and transition radii

- Accept natural wall thickness variation

- Keep draw ratios conservative

- Design to manage wrinkling, tearing, and earing

- Pierce holes after drawing when accuracy matters

Early input from your manufacturer prevents redesigns later in the program.

Scaling from Prototype to Production

Deep drawn parts often behave differently at prototype and production volumes.

As volume increases:

- Tooling becomes more refined

- Process controls tighten

- Inspection methods become standardized

- Secondary operations may be integrated

Designs created with scalability in mind transition more smoothly into high-volume metal stamping.

Quality and Process Controls Engineers Should Expect

Typical controls include incoming material verification, in-process dimensional checks, tool wear monitoring, and final inspection based on print requirements. Formal quality systems support repeatability and traceability.

What Engineers Should Take Away

Deep drawn metal stamping is not just about forming depth. It is about understanding how material flows, where variation is unavoidable, and which features should be controlled through design versus secondary operations.

Engineers who get the best results from deep drawn stampings typically:

- Design parts around natural material behavior instead of fighting it

- Allow non-critical features to remain form-controlled

- Specify tight tolerances only where function demands it

- Engage manufacturing input early to reduce redraws and secondary work

- Design with production scale in mind, not just prototype feasibility

When these principles are applied early, deep drawing becomes a highly repeatable, cost-effective process for high-volume metal components.

When It Makes Sense to Involve a Manufacturer Early

Manufacturing input is most valuable when:

- Draw depth or draw ratio is aggressive

- Wall thickness consistency is critical

- Secondary operations are driving cost

- Hole placement or post-draw features affect function

- The part must scale reliably into high-volume production

Early collaboration helps identify design adjustments that reduce tooling complexity, improve yield, and stabilize long-term production.

Contact Us

If you are designing or sourcing a deep drawn metal stamping and want feedback on tolerances, cost drivers, or manufacturability, contact Accurate Forming to discuss your application.