Frequently Asked Questions for Deep Drawn Suppliers About Deep Drawn Tubes

Frequently Asked Questions for Deep Drawn Suppliers About Deep Drawn Tubes

May 19, 2015

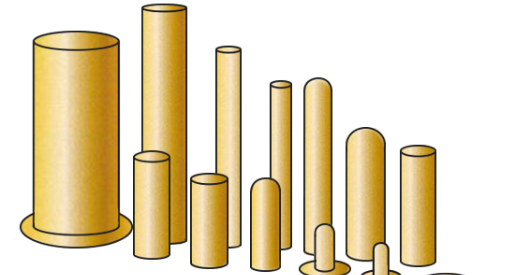

The deep draw process is very well known for manufacturing products such as caps, ferrules, and other small items, but can often be overlooked as an option when the project calls for tubes. No doubt, this is due to some common misconceptions regarding the capabilities of the latest deep drawn stamping technology.

Deep drawn tubes have a host of benefits as compared to other methods of manufacturing tubes that can make the deep drawn process the best choice for many projects. Asking the right questions can greatly help the decision making process.

Here then, are a few of the most frequently asked questions regarding deep drawn tubes and their answers.

Q: Why choose the deep drawn process for tubes when there are many other alternatives?

A: The deep drawn process creates tubes that are seamless, concentric, and part per part lower cost than other methods. The seamless nature of deep drawn tubes means no corrosion problems long term, no leaking issues, and a concentric shape that makes assembly designs much less complex.

Q: Will the material choices be limited?

A: No. Almost any material that can be deep drawn can also be drawn into tubes. As always, it’s best to talk with the supplier regarding any limitations in material.

Q: What is the maximum length of a deep drawn tube?

A: The deep draw process is capable of creating tubes up to 450mm in length using some materials. For example Accurate is capable of creating tubes up to 138.17mm.

Q: Can I include secondary operations in the process?

A: Absolutely. One of the benefits of the deep drawn process over others is that value added operations such as slitting or notching, typically associated with secondary steps, can be performed simultaneously.

Q: I have heard that deep draw stresses the material. Will my part be weaker than other methods?

A: The deep drawn method does stress the material. This does not weaken the part, but rather makes it even stronger through a process known as cold working. Your deep drawn part will actually be stronger, and more resistant to corrosion that those created by other methods.

As with any other deep draw project, good communication with the supplier is the key to a successful product. Always make sure to ask plenty of questions. Your supplier is an expert in the field and will be glad to help.