Posts by accurateforstg

Signs Your Deep Drawn Supplier Doesn’t Know What They’re Doing

Signs Your Deep Drawn Supplier Doesn’t Know What They’re Doing

Signs Your Deep Drawn Supplier Doesn’t Know What They’re Doing

April 23, 2015

Like any other product or service, there are always choices when selecting a deep drawn supplier. And like any other project, you want to find the one who will provide the parts that you need, at the best cost available. Problem is, as the customer, deep drawn stamping is not your specialty. So you contact a few suppliers for quotes and maybe a few prototype parts, and now you are sitting at your desk with samples of deep drawn parts, trying to decide which is best.

Things to Consider When Having Small Deep Drawn Parts Made

Things to Consider When Having Small Deep Drawn Parts Made

Things to Consider When Having Small Deep Drawn Parts Made

April 21, 2015

They say that the devil is in the details. Anyone who has managed an engineering or manufacturing project will certainly attest to the validity of that statement. When the decision has been made to change the manufacturing method of a part from one method to another, it’s the fine details that can often be overlooked and add up to major issues down the road.

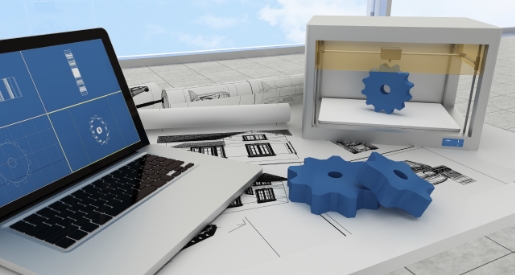

What Does 3D Printing Mean for the Future of Part Manufacturers

What Does 3D Printing Mean for the Future of Part Manufacturers

What Does 3D Printing Mean for the Future of Part Manufacturers

April 16, 2015

Sometimes, the best way to know the future is to understand the past.

A Few Quick Tips to Find the Best Deep Drawn Part Company

A Few Quick Tips to Find the Best Deep Drawn Part Company

A Few Quick Tips to Find the Best Deep Drawn Part Company

April 14, 2015

We all want the most value for our money. It’s human nature. Add to that a few demanding stakeholders and project budgets, and the need to find the best suppliers for your products becomes even stronger.

5 Common Deep Draw Problems and How to Avoid Them

5 Common Deep Draw Problems and How to Avoid Them

5 Common Deep Draw Problems and How to Avoid Them

April 9, 2015

Although the finished product might look simple, and no doubt the experts make it look easy, the deep drawn process is actually one of the most complicated methods of manufacturing available. The act of forcing metal into a given shape introduces a host of possible problems and concerns. To the trained eye, the finished product can tell a very clear story about the quality of the process.

The Biggest Misconceptions Facing Precision Metal Stamping Industries

The Biggest Misconceptions Facing Precision Metal Stamping Industries

The Biggest Misconceptions Facing Precision Metal Stamping Industries

April 7, 2015

In the manufacturing world, there are always many different paths to the same outcome. Several machining processes are capable of producing very similar, if not exact, parts for many different industries and products. The company developing the product is faced with the decisions regarding what type of process would provide the best quality at the lowest cost.

5 Statistics You Won’t Believe about the Manufacturing Industry

5 Statistics You Won’t Believe about the Manufacturing Industry

5 Statistics You Won’t Believe about the Manufacturing Industry

March 31, 2015

Numbers, and the meanings behind them, drive the vast majority of the decisions we all make every day. Whether it’s the price of a new car or that shiny new tech gadget, or the chances that our favorite football team will win the next championship, we all rely on numbers to provide in-depth information about what we want to know.

How Deep Drawn Project Management Works

How Deep Drawn Project Management Works

How Deep Drawn Project Management Works

March 24, 2015

By definition, any collection of activities that function towards the same goal can be called a project. These projects can be typical, meaning that they share similar functions each time they are executed, or unique and specific to one particular outcome. The act of initiating, controlling, and completing these projects is considered project management.

The Evolution of Deep Drawn Inventory Management Programs

The Evolution of Deep Drawn Inventory Management Programs

The Evolution of Deep Drawn Inventory Management Programs

March 17, 2015

The world was a different place fifty years ago. There were no computers, no cell phones, and if someone asked you to message them you wrote words on sheets of paper, folded it neatly, and mailed it. Depending on the distance, it might have taken a day or even a week for your message to be read.

Should You Care about Working with an ISO Certified Company?

Should You Care about Working with an ISO Certified Company?

Should You Care about Working with an ISO Certified Company?

March 10, 2015

Certifications.

We all know they are important factors that can alter our perception of virtually any company, organization, or even individual. The right certification or registration means that the company has gone the extra mile to comply with the highest standards available.

The auto mechanic at your local garage or dealer might be ASE certified, lawyers are required to be board certified, and we certainly all look for the right certifications when choosing a doctor for our family. In the manufacturing industry, companies who have proven the willingness to excel achieve the title ISO Certified.

Knowing the right certifications to look for is only part of it, however. Knowing what they mean, and how they apply to the company or service you are considering is even more important.

ISO 9000 certification sets the standards for businesses that want to ensure that their products and quality always meet the customer’s highest expectations. An ISO certified company has embarked on a long and difficult process to bring their business to a higher level. Through dedication, planning, and excellent management these companies are diligent in the details.

The ISO 9000 family of certification includes the 9001:2008 certification. This certification standard is based on strong customer focus, top management motivation, and a continuing passion for improvement using a process management approach.

An ISO certified company has been inspected and audited many times over by specific third party accredited certification bodies. Achieving the standard once is not enough. To wear the ISO badge, companies must constantly maintain the highest standards and strive to improve in every facet of operation.

Knowing the details behind this sort of achievement, the choice becomes simple. When you find a vendor who proudly displays their ISO certification, you can be confident that customer service, accuracy, and integrity are the mainstays of operation.

Becoming an ISO certified company isn’t easy, nor is it required by any law. Companies who have taken the extra step have done so of their own accord, to prove themselves to their customers and to the market. They do it to stand out from the rest. To be tested and not found lacking.