Posts by accurateforstg

A Brief History of Marker Pen Components

A Brief History of Marker Pen Components

A Brief History of Marker Pen Components

July 9, 2015

The ubiquitous pen has a long and storied history. From the first uses of a feather to scribe upon papyrus to the modern, ballpoint, the pen and specifically the marker pen, has changed the way we write as a whole.

Premium Writing Instruments as Works of Art

Premium Writing Instruments as Works of Art

Premium Writing Instruments as Works of Art

July 7, 2015

Best Materials to Use When Deep Drawing Medical Components

Best Materials to Use When Deep Drawing Medical Components

Best Materials to Use When Deep Drawing Medical Components

June 30, 2015

Over the decades, medical instruments have evolved from crudely crafted and rustic devices into what many might feel are modern works of manufacturing art. As the techniques of industry changed in line with new and tighter regulations, the resulting products became more precise, more reliable, and definitely more sanitary.

In the medical industry, sanitation is king. The drive to maintain a sterile environment regulates everything from the clothing worn by staff, to the materials used in the manufacture of the equipment that everyday saves countless lives all over the world. From the smallest needle to the most complex scanning device, every part must be diligently designed with sterility in mind.

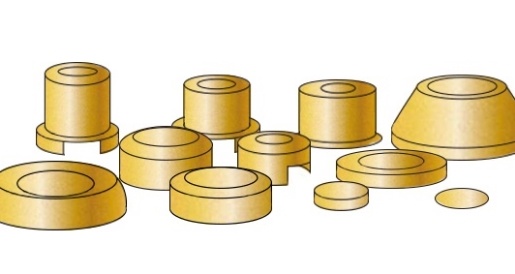

Many of the instruments used in the medical industry are produced using the deep drawn process, as the characteristics of deep drawn parts match perfectly with the stringent requirements for medical use. In order to meet sterility demands, the materials chosen for deep drawing medical components are also carefully considered.

The term ‘stainless steel’ is one commonly heard when discussing manufacturing, although it can sometimes be misleading. There are many types of stainless steel available, and not all are suitable for medical use. Stainless steel gains its desired properties from the introduction of nickel to the composition, an element that can cause allergies in many humans. A unique alloy of stainless, called “surgical steel” contains very limited amounts of nickel yet maintains the corrosion resistant properties that make stainless a reliable material for deep drawing medical components.

Another common material used in the manufacture of medical devices is copper. While copper is sometimes mistakenly considered a less refined metal, modern alloy compositions allow for the production of components that meet the rigorous sanitation requirements yet retain the many desirable properties of pure copper. As a material, copper is naturally anti-microbial, meaning simply that biological microbes (bacteria) are unable to live and multiply on the surface, which helps in maintaining a sterile environment.

When the device requires exceptionally high strength, titanium is certainly the most popular choice. As a material, titanium is corrosion resistant, acid resistant, and exhibits extremely high tensile strength. Deep drawing medical components using titanium creates products that have a highly rigid natural grain structure, which is further enhanced by the work hardening of the deep draw process. Titanium products are well known to survive extensive lifetimes even in the harshest, most abusive environment; the human body.

Deep Drawn Products That Dentists Use

Deep Drawn Products That Dentists Use

Deep Drawn Products That Dentists Use

June 23, 2015

When it comes to the medical industry, there are few places more intimidating than the dentist’s office. No matter what gizmo the dentist is using, to the patient it no doubt appears absolutely medieval. To us, the strange looking contraptions used to peer and poke around in our mouths have the ominous look of something intended for far more sinister purpose.

After all of the fuss however, we all discover very quickly that in the hands of a dedicated professional, these devices are important tools in the care and protection of our precious, and only, set of teeth. The craftsmanship and quality of the delicate instruments might not be foremost in our minds, but they definitely are to the manufacturers who create them, as well as the skilled hands that use them every day.

The deep draw process has long been used in the production of the casings and protective shells for many of these delicate precision instruments. With a wide selection of available materials, highly accurate tolerances, and a vast array of possible finishes and coatings, deep drawn products have become one of the premier choices for manufacturing medical and dental instruments.

Dentists of today have a variety of sophisticated and elegant tools at their disposal. As a prime example, the advent of laser technology has provided new and innovative methods for performing exceedingly detailed procedures that previously would have required invasive surgery. Developing a laser system that is controllable enough for surgical work was no small task, however. Designers knew that the tool casings would need to be precise, durable, ergonomic, and constructed from sophisticated materials, all at a cost that made economic sense.

As a deep drawn product, the new laser technology devices became reality. With the ability to craft high precision casings from a variety of rare and exotic materials, quickly and with low cost, the application of deep drawn technology has made even intricate devices such as these both possible and affordable.

Deep drawn products have found their way into the medical and dental industry worldwide. The speed and low cost-per-part of the deep draw process provides excellent economic value to the industry, while the ability to craft high precision components from a host of different materials provides the versatility needed to remain a preferred provider.

3 Deep Drawn Medical Devices That Could Save Your Life

3 Deep Drawn Medical Devices That Could Save Your Life

3 Deep Drawn Medical Devices That Could Save Your Life

June 18, 2015

To most people, the manufacturing industry and the medical field have virtually nothing in common. Just the word manufacturing brings to mind visions of gritty, dark factories where noisy machines crank along, producing all manner of parts and products that somehow become the things we use every day. Most of us pay little attention to the process, we just happily accept that our gadgets and gizmos will be available when we want them, and will work without fail.

Where Did the Deep Drawing Process Start?

Where Did the Deep Drawing Process Start?

Where Did the Deep Drawing Process Start?

June 11, 2015

The process of deep drawing metals to create products is rapidly becoming one of the premier methods of manufacturing. The low cost, high production speeds, and excellent finished quality of the parts has made the deep draw process a popular choice for design engineers. Most definitely the deep drawing process is well-known today, but where did it all begin?

Why the Deep Drawn Process Is Perfect for the Medical Industry

Why the Deep Drawn Process Is Perfect for the Medical Industry

Why the Deep Drawn Process Is Perfect for the Medical Industry

June 9, 2015

How Deep Drawn Ordnance Parts Help Protect the Military

How Deep Drawn Ordnance Parts Help Protect the Military

How Deep Drawn Ordnance Parts Help Protect the Military

June 4, 2015

It might not seem evident, but safety is a prime concern for members of the military. The men and women in the armed forces place themselves in harm’s way on an almost daily basis. They rely on training, skills, and properly manufactured equipment to ensure that the inherently dangerous activities they perform are as safe as possible.

Some of the safety equipment is obvious; a well-designed parachute, solidly crafted snap rings securing rappelling harnesses, even the sturdy leather boots that help protect the feet and ankles. All of these things are critical to protecting the lives and safety of the armed forces.

Often overlooked for their contribution to safety are the quality standards that are met by the manufacturers who provide the most critical of equipment, such as weapons and ammunition. Known as ordnance, it is the quality and reliability of these devices that can make the difference between a typical day of training, and a catastrophe.

All products that are manufactured for use by the military are required to meet a unique set of standards known, rightly enough, as Military Specification, or Milspec.

Deep drawn ordnance is no different. In order to ensure the proper function, strength, and tolerances, all military ordnance produced using the deep drawn method is inspected carefully to meet the stringent requirements of Milspec.

The design of military ammunition is far more precise than one might imagine. Consider for a moment the function of the brass casing during operation; the primer must be secure and located correctly, the outer dimension must be accurate and concentric, and the casing wall must withstand the force of what amounts to an explosion when fired. If any of these criteria are not met, disaster can occur.

Since the casing for a round of ammunition is for the most part a deep drawn can, the manufacturing process remains basically unchanged. The naturally seamless design and uniform wall thickness of deep drawn ordnance lends significant strength to the ammunition, which ensures the safety of the soldier firing the weapon. Additionally, the added strength in key areas of the design created through the work hardening effect of the deep drawn process provides further reliability of the product.

Deep drawn ordnance is fast becoming the primary choice for military projects, with good reason. Compared to other manufacturing methods for the same design, deep drawn products are lower cost, higher quality, and safer.

What Do People Use Deep Drawn Shells For?

What Do People Use Deep Drawn Shells For?

What Do People Use Deep Drawn Shells For?

June 2, 2015

There are many things around us all that we overlook, or take for granted. Most are small, seemingly unimportant details that we hardly notice. We call them trim, or finishing, or molding, and we only really notice when they become damaged or discolored.

The Best Way to Respond to Unresponsive Deep Draw Suppliers

The Best Way to Respond to Unresponsive Deep Draw Suppliers

The Best Way to Respond to Unresponsive Deep Draw Suppliers

May 28, 2015